250 pieces/carton and 200 cartons/per pallet

delivery: 10 days

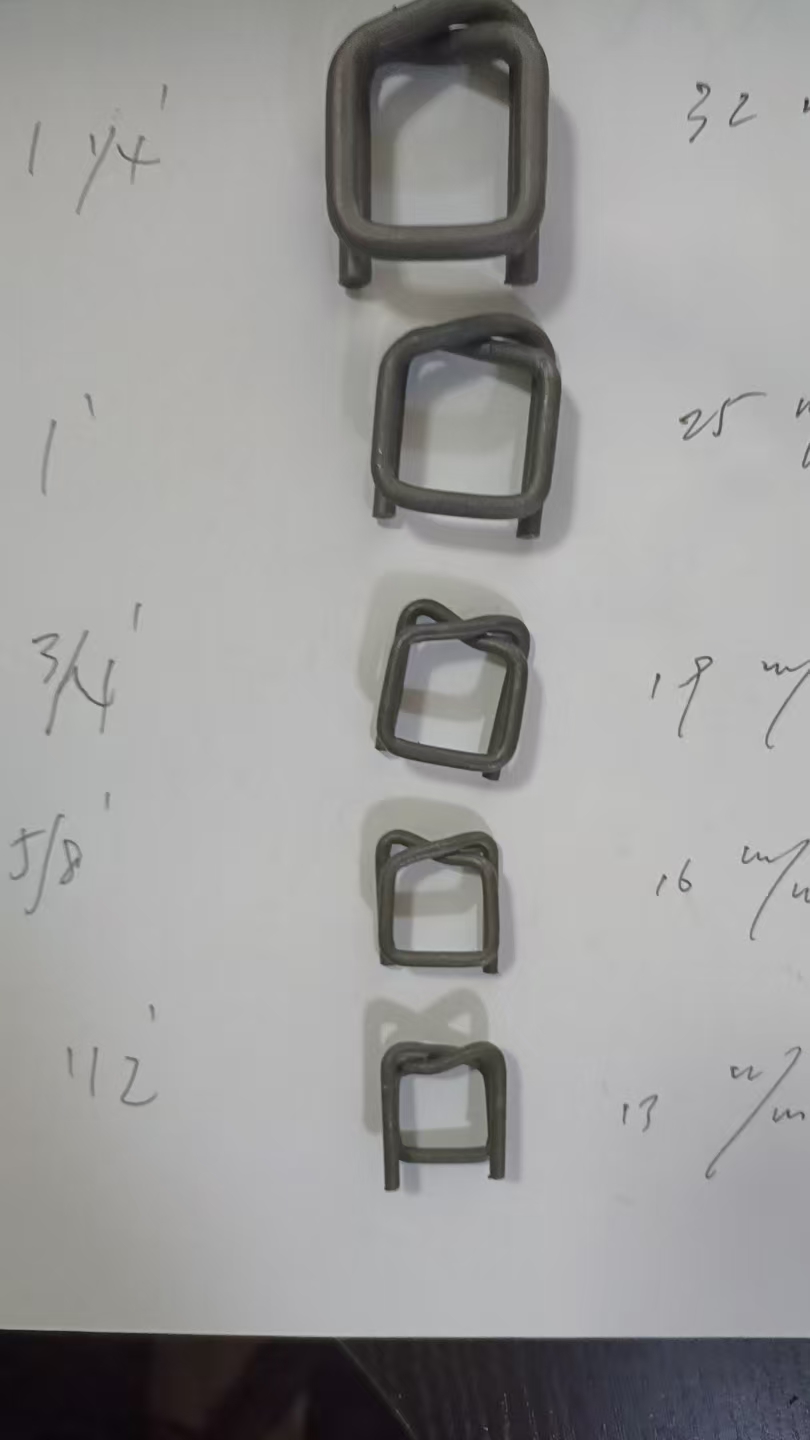

1. General Overview The 32 x 7 mm corded strap buckle is a heavy-duty metal buckle designed for securing 32 mm wide composite corded polyester straps, commonly used in industrial packaging applications such as securing steel pipes, steel strapping, or palletized loads for export (e.g., to Ecuador or Algeria). • Purpose: To provide a strong and reliable connection for 32 mm composite corded polyester straps, ensuring load stability during transportation. • Compatibility: Designed for 32 mm wide polyester composite corded straps with a PP coating (e.g., 0.15 mm per side, as previously discussed).

2. Dimensional Specifications • Width (Strap Compatibility): 32 mm (1.26 inches) o Matches the width of the composite corded polyester strap to ensure a secure fit. • Wire Diameter: 7 mm (0.276 inches) o Refers to the thickness of the steel wire used to form the buckle, providing structural strength. • Overall Dimensions (Approximate): o Length: 40–45 mm (to accommodate strap width and folding). o Height: 15–20 mm (including wire bends). o These dimensions are typical for 32 mm buckles based on industry standards [Web ID: 0] [Web ID: 5]. • Inner Opening: o Designed with a central opening to allow the 32 mm strap to be folded double and passed through, typically 34–36 mm wide to accommodate the strap’s thickness (e.g., 0.8–1.0 mm total thickness with a 0.15 mm PP coating per side).

3. Material and Finish • Material: High-strength steel wire o Typically made from durable, corrosion-resistant wire steel to withstand high tensile forces [Web ID: 7] [Web ID: 16]. • Surface Finish Options: o Galvanized: Zinc coating (per ASTM A123) to protect against rust, ideal for humid environments like Ecuador (e.g., Guayaquil’s 70–90% humidity) [Web ID: 0] [Web ID: 5]. Zinc Coating Thickness: 10–15 µm (0.4–0.6 mils). Corrosion Resistance: ≥500 hours in salt spray test (ASTM B117). o Phosphated: Alternative finish with a phosphate coating for additional grip and corrosion resistance, often used with woven or composite straps [Web ID: 8] [Web ID: 14]. Corrosion Resistance: ≥300 hours in salt spray test (ASTM B117). • Weight: Approximately 50–60 grams per buckle (based on similar 32 mm buckles) [Web ID: 0].

4. Performance Characteristics

• System Strength: o When used with a 32 mm composite corded polyester strap (e.g., 1500 daN linear breaking strength, as per [Web ID: 0]), the buckle ensures a system strength of 60–90% of the strap’s linear breaking strength. o Example: For a 1500 daN strap, system strength = 2 × 1500 × 0.8 (buckle efficiency) = 2400 daN (approximately 2400 kg) [Web ID: 8] [Web ID: 17]. • Tensile Load Capacity: o The 7 mm wire diameter ensures the buckle can handle loads up to 2000–2500 kg without deformation, depending on the strap’s strength [Web ID: 8]. • Joint Efficiency: 75–90%, meaning the buckle maintains a high percentage of the strap’s breaking strength at the joint [Web ID: 1] [Web ID: 8]. • Temperature Range: o Suitable for -40°C to 80°C (-40°F to 176°F), compatible with PP-coated polyester straps and humid environments like Ecuador. • Corrosion Resistance: o Galvanized buckles resist rust in humid conditions for 5–10 years; phosphated buckles offer slightly less corrosion resistance but better grip for strap retention [Web ID: 0] [Web ID: 14].

5. Design Features

• Structure: o Wire buckle with a rectangular shape and a central opening for strap passage. o The strap is folded double, passed through the opening, and secured by pulling tight, often with a tensioner [Web ID: 7] [Web ID: 16]. • Grip Mechanism: o Phosphated versions have an enhanced grip to prevent strap slippage [Web ID: 14]. o Galvanized versions provide smooth threading while maintaining hold [Web ID: 0]. • Ease of Use: o Designed for manual or tensioner-based application (e.g., with a heavy-duty tensioner for 32 mm straps) [Web ID: 24].

6. Applications

• Primary Use: Securing heavy loads such as 4-inch/5-inch Schedule 40 steel pipes (e.g., 41.78 kg for 2.6m 4-inch pipe) or 9mm blued steel strapping for export to Ecuador or Algeria. • Industries: Construction, logistics, steel manufacturing, agriculture (e.g., securing pipes, metal bundles, or palletized goods). • Environmental Suitability: Ideal for humid and coastal environments due to corrosion-resistant finishes [Web ID: 0].

7. Standards and Testing

• Manufacturing Standards: o Conforms to ASTM A123 (for galvanized finish) and ISO 9001 (for quality control) [Web ID: 0] [Web ID: 8]. • Testing: o Salt Spray Test (ASTM B117): ≥500 hours (galvanized), ≥300 hours (phosphated). o Tensile Test: Ensures system strength of 60–90% of strap’s linear breaking strength [Web ID: 8]. o Adhesion Test (for coating): No peeling or flaking of zinc/phosphate coating.

. Packaging and Availability • Packaging: Typically supplied in boxes of 250 pieces (standard for 32 mm buckles) [Web ID: 0] [Web ID: 5]. • Weight per Box: Approximately 12.5–15 kg (250 × 50–60 grams). • Availability: Compatible with 32 mm composite corded polyester straps (e.g., 1500 daN, 32 mm x 300 m rolls) [Web ID: 0].